SOIL

CARBON AND CLIMATE CHANGE NEWS

From

Consortium for Agricultural Soils

Mitigation of Greenhouse Gases (CASMGS)

http://soilcarboncenter.k-state.edu

Charles W. Rice, K-State Department of

Agronomy, National CASMGS Director

(785) 532-7217 cwrice@ksu.edu

Scott Staggenborg, K-State Department of

Agronomy (785) 532-7214 sstaggen@ksu.edu

Steve Watson, CASMGS Communications (785)

532-7105 swatson@ksu.edu

renewable energy

and

greenhouse gas emissionS

One of the ways agriculture is helping

reduced greenhouse gas emissions is through the production of renewable fuels

such as ethanol -- especially cellulosic ethanol. Corn-based fuel ethanol can

achieve moderate reductions in greenhouse gas (GHG) emissions compared to

gasoline, according to a report from Argonne National Laboratory. But cellulosic

ethanol can achieve much greater reductions in GHG emissions compared to gasoline.

See page 35 of the presentation at: http://www.transportation.anl.gov/pdfs/TA/347.pdf

The most detailed analysis of GHG

emissions from ethanol is in a report titled “Effects of Fuel Ethanol Use on

Fuel-Cycle Energy and Greenhouse Gas Emissions” from Argonne National

Laboratory. This report can be found at: http://www.ipd.anl.gov/anlpubs/1999/02/31961.pdf

The authors of this report calculated the

effect of various blends of ethanol-gasoline on GHG emissions, on the basis of

“Per Vehicle Mile.”

Current technology, corn-based ethanol:

* Use of E10 results in a 1 percent

reduction in GHG emissions

* Use of E85 results in a 14-19 percent

reduction in GHG emissions

Near-future technology, biomass-based (cellulosic)

ethanol:

* Use of E10 results in a 6-9 percent

reduction in GHG emissions

* Use of E85 results in a 68-102 percent

reduction in GHG emissions

E10 is a blend of 10 percent ethanol and

90 percent gasoline. E85 is a blend of 85 percent ethanol and 15 percent

gasoline.

The wide range of emissions reductions for

biomass-based ethanol reflects the different possible feedstocks that could be

used. Cellulosic ethanol made from herbaceous biomass achieves smaller

reductions in GHG emissions than does cellulosic ethanol from woody biomass.

How can ethanol result in greater than a

100 percent reduction in emissions (e.g. E85 ethanol from biomass)? This is

attributable to the elimination of emissions from electric power plants. Electricity

generated in cellulosic ethanol plants, because of the plant design, exceeds

the internal needs of the plant. The excess is exported to the electric grid,

reducing emissions from other generators of electricity.

The bottom line is that cellulosic ethanol

can potentially achieve significant energy and GHG emissions reduction benefits.

The production and use of ethanol has a

fundamentally different impact on the CO2 cycle than the production and use of petroleum

fuel. The impact is different for grain-based than biomass-based ethanol

production. The production of grain-based ethanol requires more inputs than

biomass-based ethanol, which affects the overall GHG emissions balance. And

grain-based ethanol production has a more uncertain effect on soil carbon

sequestration and sustainability than cellulosic ethanol production.

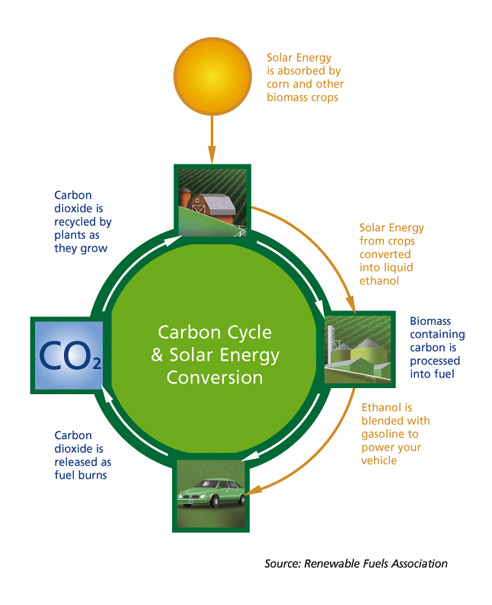

The basic carbon/ethanol cycle is:

There are four primary reasons that the

production and use of ethanol reduces GHG gas emissions.

1. Less CO2 is emitted from the tailpipe when burning ethanol

instead of gasoline. Burning ethanol (from any source) releases less CO2 into

the atmosphere than gasoline, according to a report from the Energy Information

Administration (EIA), U.S. Department of Energy. See: http://www.eia.doe.gov/cneaf/alternate/page/environment/chap3.html

Ethanol releases

325.5 grams of CO2 per vehicle mile traveled, compared to 347.3 grams for

gasoline. Ethanol does release much more water vapor into the atmosphere than

gasoline per vehicle mile traveled. Currently, however, water vapor from fuel combustion

is not believed to have a significant impact on atmospheric water vapor

concentrations, according to the EIA report.

2. The carbon-based energy captured in grain and plant materials is

used directly as a fuel source, completing the carbon cycle. Plants take CO2

from the atmosphere and convert it to carbohydrates using the sun as an energy

source. The carbon is then converted within an ethanol plant into combustible

fuel, which enters the atmosphere when it is burned by vehicles. These carbon

emissions are then used by next year’s crop and the cycle is complete.

When plant

materials are not used for ethanol, part of the carbon is eventually

sequestered in the soil and part is emitted into the atmosphere as the plant

material decomposes on the soil surface. When plant materials are used for

ethanol, the portion of the carbon that would normally be decomposed and released

into the atmosphere is instead used to replace fossil fuel combustion.

3. With perennial biomass-based ethanol crops, there is an

increase in the amount of root mass and an elimination of tillage. This results

in an increase in the amount of carbon sequestered in the soil. Also, the lignin

by-product of cellulosic ethanol production can be used to at least partially

fuel the operation of the ethanol production plant itself, meaning less

reliance on coal, natural gas, or other fuels. The CO2 emissions released by

the combustion of lignin to fuel the ethanol plant are treated as zero because

they are taken up again by the corn or biomass plants during photosynthesis.

4. Cellulosic ethanol plants can potentially generate excess

electricity from the combustion of lignin through co-generation facilities, and

that electricity is exported to the power grid. This direct offset reduces the

emissions that would have come from the normal process used by the power plant.

There is some variability in the amount of GHG emissions reductions

from renewable energy because of many factors, such as the:

* Different types of fuel used to operate ethanol production

plants. Many ethanol production plants currently use coal or natural gas as the

primary energy source in their operations. Plants that use biomass combustion

to fuel the plants have the most favorable GHG emissions balance.

* Amount of inputs needed to raise the ethanol feedstocks. With

corn-based ethanol, considerable nitrogen fertilizer is used in the production

of corn. The potential nitrous oxide emissions from the increased fertilizer

use offsets some of the benefits of reduced CO2 emissions.

* Fuel use in feedstock production. The amount of equipment time

used in the production of the feedstock will have an impact on the overall GHG

emission budget.

* Soil management and tillage practices. If soils are subject to

increased erosion or tillage intensity during the production of biofuels, this

can cause an increase in carbon emissions from land use changes and offset some

of the benefits.

* Yield of the feedstocks compared to the inputs used. Corn

producers are getting higher yields per unit of input now than in years past,

which improves the overall energy and GHG emissions balance.

* Method and distance of transportation needed to take the ethanol

from the production plant to the end user.

The estimates on GHG emissions reductions

from the production and use of ethanol are based on the GREET model (Greenhouse

gases, Related Emissions, and Energy use in Transportation) from the Center for

Transportation Research at Argonne National Laboratory. For details of the

GREET model, see:

http://www.transportation.anl.gov/modeling_simulation/GREET/index.html

-- Steve Watson, CASMGS Communications